| But, why universal joints at all ? Building on oscillating coupling

rods we get down to Two gears as well, which are necessary

only to get "round the corner" to the pointer. Sr. R.G. Torrent entered

this idea, but failed to implement it.

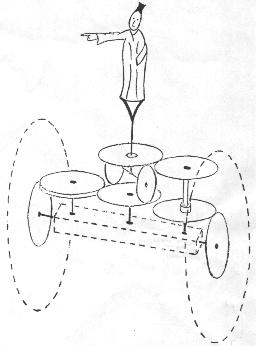

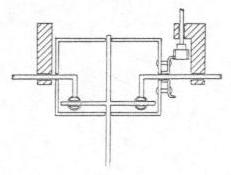

Explanation: If both halfshafts in the picture to the left rotate at

the same speed, but in opposite direction, the "cross" in the middle will

move up and down while swinging round the vertical axis. If the speeds

differ, the "box" guiding the up and down movement will have to rotate.

For the chariot you will need two of these assemblies - one to reverse

the rotation of one roadwheel ("box" fixed to frame !) and one with rotatable

box as depicted to extract the motion for the pointer (vertical axis to

the upper right). |

|